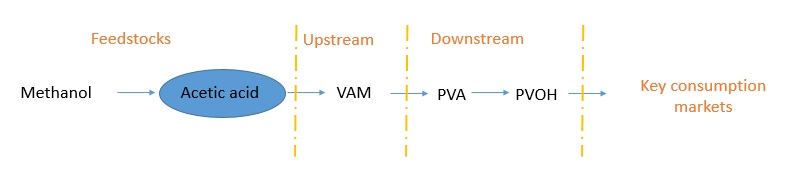

Bioplastics could become viable substitutes for petroleum-based products, and bio-acetic acid may be a good example of such substation. Of course, the capacity to substitute petroleum-based products by ‘green’ alternatives depends on multiple factors, including their production costs, oil prices, regulatory initiatives, to name only a few. Standard acetic acid is a large-volume chemical which acts as a building block in a long value-generating polymer chain. This value chain comprises petroleum-based raw materials (e.g. ethanol, methanol, acetic acid, etc.), upstream products (e.g. vinylacetate monomer), downstream products (polyvinyl acetate, polyvinyl alcohol, acetic anhydride, etc.) and finally key consumption markets (e.g. solvents, adhesives, etc.).

An example of the polymer value chain for acetic acid

As a matter of fact, no other large-volume chemical could match acetic acid in its variability of production methods and feedstocks. Acetic acid could use, for instance, both ethanol and methanol as a feedstock. To this extent, bio-acetic acid can easily be a part of such chain. For instance, Wacker has piloted a technology to produce bio-acetic acid at its plant in Burghausen, Germany (Wacker’s acetic acid facility in this city has been idled). The process involves biomass as a feedstock, which is then converted to ethanol and later to acetic acid via ethylene oxidation. There are also several other routes to produce bio-acetic acid that are being studied by Wacker. As alluded before, their economics is governed by a range of factors. Ironically, current low crude oil prices hinder the development of the bio-acetic acid market.

More information on the acetic acid market performance can be found in the insightful research study “Acetic Acid (AcOH): 2016 World Market Outlook and Forecast up to 2020”.