Aniline is an important chemical compound applicable in a variety of industries, including dye, pharmaceutical, biomedical, rubber and other industries. It is also a vital intermediate in the methylene diphenyl diisocyanate (MDI) production, comprising the route consisting from nitrobenzene, aniline, MDI and polyurethanes.

This route is favoured by many leading aniline producers, like Germany’s Covestro. Covestro is a Bayer’s spin-off company formed in the fall of 2015; it was formerly known as Bayer MaterialScience.

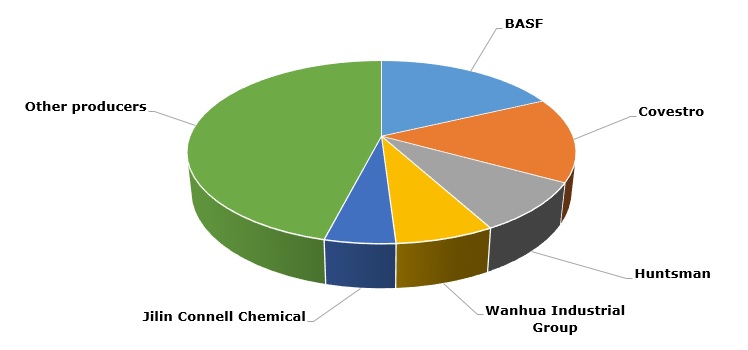

Aniline: structure of the world’s production capacity by major manufactures

Though this route is the most common way to produce and use aniline as nitrobenzene still remains the classical feedstock for aniline manufacture, there is no shortage of endeavours to revolutionize and innovate the aniline-manufacturing process. For instance, Du Pont has developed an interesting new aniline production process relying on benzene and ammonia, which are reacted over a NiO/Ni catalyst containing promoters including zirconium oxide.

However, the most innovative aniline production process is being developed by aforementioned Covestro. Covestro has developed a technology to make aniline out of waste sugar biomass, which is a renewable raw material. Waste is then converted to acid biologically with the help of microorganism-based catalysts, and chemical catalysts are further employed to make aniline. The process still awaits commercialization, but if it is successful, the prospects of implementing this process in aniline production are simply enormous, meaning smaller carbon footprint, less dependence of fossil fuels in the plastics industry and other benefits.

More information on the aniline production can be found in the in-demand research study “Aniline: 2017 World Market Outlook and Forecast up to 2027”.