Soda ash has the following main outlets: glass (both container and flat), detergents, soaps, chemicals, as well as metallurgy, pharmaceuticals, environment protection (e.g. acidity combating) and other applications. The natural route of soda ash production involves trona ore purification.

Trona ores are mostly deposited in North America. For instance, an underground trona mine located in Green River (Wyoming, the US) and owned by Solvay Chemicals, Inc. operates as a source of natural soda ash. A substantial methane leak occurred at this mine in late October 2018, which adversely affected mining operations (the mine returned to normal work in late November 2018). This accident resulted in the immediate curtailment of Solvay’s natural soda ash inventories in the US, but Solvay’s well-developed soda ash production and logistics networks have mitigated the negative effects so there was no shipment disruption for customers. Currently, Solvay has encountered with strong demand for soda ash from local consuming sectors, as well as with rising associated energy and delivery costs, which provide a downward pressure on the company’s margins. Soda ash supply, at least in the US market, is characterised as tight, and the accident in Green River could only exacerbate the situation.

Solvay Chemicals operates a natural soda ash facility in Green River with a capacity of c. 2.5 mln mt/y. In total, Solway, which is a parent organization for Solway Chemicals, has a total global soda ash capacity of over 7.6 mln mt/y and is the largest soda ash manufacturer in the world, covering both regional and export markets. The company has 8 soda ash facilities in Europe and North America, accounting for about 20% of North American capacity and c. 40% of European capacity.

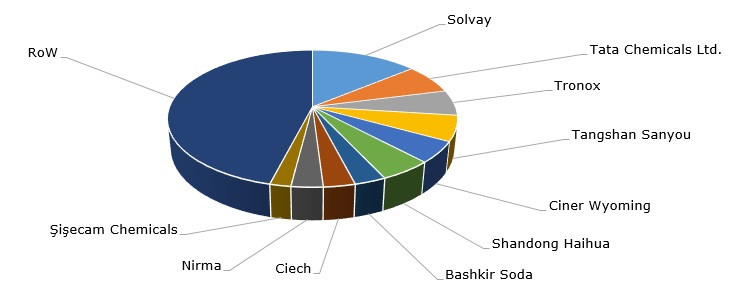

Top 10 soda ash manufacturers

Since natural trona deposits are rare, soda ash is mostly produced with the help of a synthetic process, despite the fact that synthetic soda ash is more expensive. It is interesting that Solvay uses both ways of soda ash production. Firstly, it is the traditional ammonia process, which bears the name of Ernest Solvay, (the founder of Solvay) and results in synthetic soda ash production (via Solvay’s European facilities). Secondly, there is an above-mentioned natural route, which implies the refining of a primary source of sodium carbonate, the trona, and results in natural soda ash production (Solvay uses the natural process in the US).

Find a detailed analysis of the global soda ash market in the in-demand research report “Soda Ash: 2018 World Market Outlook and Forecast up to 2027”.