Expandable polystyrene (EPS) is a rigid cellular form of polystyrene with advanced performance in various parameters, including energy efficiency, thermal insulation capacity, air tightness, moisture resistance, durability, shock absorbing properties, compressive strength per weight, maintenance easiness, etc. Application areas for expandable polystyrene (EPS) include construction (esp. constructional insulation), packaging (esp. food containers), electronics, furniture, sports accessories, to name only a few.

The market for EPS is strongly dominated by China. However, such countries as the US, whose share of the global EPS market is rather small, do not particularly rely on China for its EPS. The Chinese EPS export to the US as a percentage of total China’s chemical exports accounts for 3.6% of the total. This is quite a small number to be affected by the recent China-US trade discrepancies and imposed tariffs.

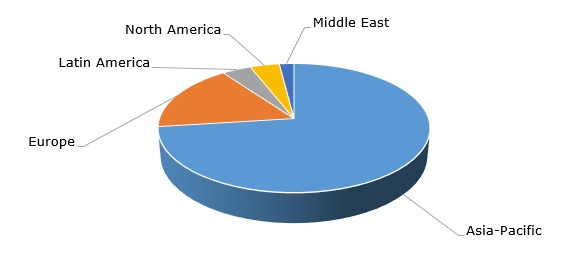

Expandable polystyrene: structure of the global production capacity by region

In the US and Canada, EPS is marketed under a colloquial name of “styrofoam”, which is wrongly attributed to it because Styrofoam, (invented by Dow Chemical scientist Otis Ray McIntire in 1941), was actually a brand name of another type of polystyrene known as extruded polystyrene.

In general, innovation plays a very important role in the EPS market development. The future of the expandable polystyrene sector is based on the production of innovative products with advanced properties and specialized functions, especially in the light that EPS packaging is under large scrutiny for its environmental impact. For instance, the city of New York joined some other cities in banning EPS package in 2015. The EPS turnover is complicated by the fact that there have been so far no viable technologies for EPS recycling or its inexpensive re-collapsing to form expanded beads again. Thus, scientists try to develop various technologies for EPS recycling. One of the prospective technologies is to use the waste of EPS and other polystyrenes as a material for gas-separation membranes.

EPS have been a well-established insulation material since approximately 1950s to be used in concrete walls, structural insulated panels, as well as roof and foundation applications. For instance, in 1951 BASF developed Styropor, a white-colour expandable polystyrene. Later, BASF launched a more advanced product called Neopor, which is a grey-colour expandable polystyrene containing graphite. Adding graphite to Neopor increased insulation performance by 20% and decreased the raw material use by 40% as compared to white EPS Styropor. In the second half of 2018, BASF increased its Neopor output by 40 thous. mt/y at its production site at Ludwigshafen, Germany. Besides, BASF announced its plan to substitute all white-colour Styropor manufactured by its plant in Ulsan, Korea (currently, 85 thous. mt/y) with grey-colour Neopor.

More information on the global expandable polystyrene (EPS) market can be found in the in-demand research study “Expandable Polystyrene (EPS): 2019 World Market Outlook and Forecast up to 2028”.