Polyphenylene sulphide (PPS) is a high-performance engineering aromatic polymer and thermoplastic material with superior characteristics of such parameters as thermal stability, chemical resistance, mechanical strength, dimensional stability, and flame resistance. A number of polyphenylene sulphide features allows manufacturing a large spectrum of its grades, which could be flexibly customised for specific needs. Polyphenylene sulphide exists in two commercially available varieties – cross-linked type and more advanced linear type. It is able to form composite combinations with other materials. It features a variety of molecular weights. Apart from all that, it has good processability thanks to a capacity to be produced by different molding processes and extrusion.

The polyphenylene sulphide market grows by 7-8% per year globally, which makes polyphenylene sulphide a highly prospective product for a range of important applications, including automotive, electronics/electrical, industrial/mechanical, aerospace and consumer/appliance equipment applications.

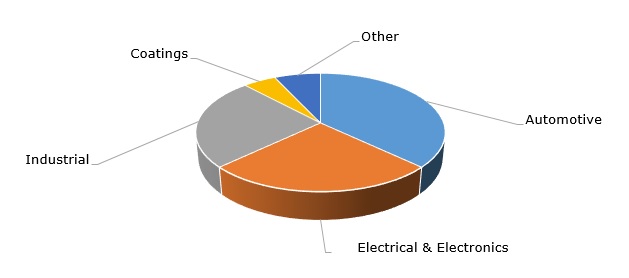

Polyphenylene sulphide: structure of the global market by application

First produced commercially by Phillips Petroleum in the United States in 1973, polyphenylene sulphide has become a commodity associated with innovative technologies and advanced materials. Its innovative character was boosted by the advances in the telecom sector, the arrival of electric vehicles and new industrial applications. The road to innovation was clearly demonstrated in the 1980s when Kureha manufactured fully linear polyphenylene sulphide, thus solving the then issue of its brittleness. One of the recent examples of such innovations is the production of polyphenylene sulphide-based composites (due to the application of synthetic graphite) with increased electrical and thermal conductivity. Poor conductivity often limits polyphenylene sulphide applicability in various sectors. Another example is Toray Industries’ development of new polyphenylene sulphide with the world’s highest flexibility level. This product employs a proprietary nanoalloy technology developed by the company. A similar level of innovation was demonstrated by Fortron grade polyphenylene sulphide manufactured by Ticona, the engineering polymers business of Celanese, or by Durafide polyphenylene sulphide launched by Polyplastics. All these confirm the innovative and high value-added character of the polyphenylene sulphide market.

More information on the global polyphenylene sulphide market can be found in the in-demand report “Polyphenylene Sulphide (PPS) 2020 Global Market Review and Forecast to 2029”.