The ongoing COVID-19 coronavirus pandemic drives the demand for isopropanol (isopropyl alcohol or IPA). Despite its fairly large level of toxicity when ingested or excessively applied to skin, the demand for isopropanol is currently boosted by its two applications – the use in hand sanitisers and in DNA/RNA extraction.

Isopropanol is known to be a key ingredient in hand sanitisers. The demand for isopropanol in this application is urgent as the COVID-19 epidemic is on the rise. It leads to the rollout of new sources of isopropanol and raises the output at existing facilities. As a result, multiple companies worldwide (e.g. Arkema, BASF, Dow Chemical, ExxonMobil, Ineos, Lyondell Basell, Monument Chemical, Shell Chemical, etc.) are either boosting or initiating isopropyl alcohol output, subject to availability of indispensable feedstock and regulatory protocols. This activity should ideally be largely facilitated by the simplification of the authorization and product rollout procedures to improve isopropanol supply to end-consumers. However, it is evident that the simplification of these measures remains slow and cumbersome which may significantly affect product availability in some regions, for instance, in Europe. It is also clear that major isopropanol capacities are located outside Europe, which complicates the supply of European customers with this indispensable commodity.

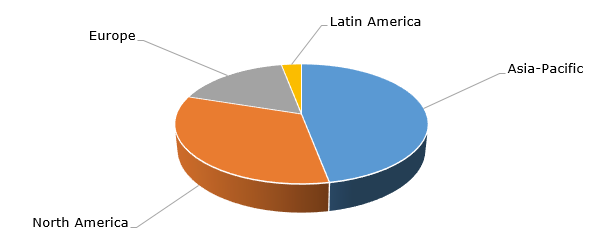

Isopropanol (IPA): structure of the global production capacity by region

Moreover, the current deficit of multiple items associated with personal protective equipment is largely created by the practices of outsourcing the production of such commodities to Asia-Pacific region.

Another important application of isopropanol is for DNA and RNA extraction, which is needed for COVID-19 testing. On average, 5 ml of isopropanol is needed for the preparation of one DNA/RNA sample. Taking into consideration the large number of samples needed for this activity worldwide, it inevitably means the increase in isopropanol output for this application.

These factors lead to the unprecedented increase in prices for isopropanol worldwide, driven by the demand for isopropanol in hospitals and other medical facilities. This leads to large volatility in prices subject to urgency, availability and other factors. For instance, in the US market, isopropanol spot prices vary in a wide range from 100 cents/lb to 270 cents/lb (or even higher) FOB Gulf.

In addition to commercial activities, major companies are donating large quantities of isopropanol to relevant medical institutions. Likewise, Huntsman (the company currently does not produce isopropyl alcohol) and LyondellBasell Industries donated large isopropanol quantities to help protect healthcare workers treating COVID-19 patients. Shell Chemical donated significant amounts of isopropanol to health institutions in the Netherlands and Canada. The company manufactures isopropanol at its plants in Pernis, the Netherlands (capacity: 150k mty) and Sarnia, Ontario, Canada (capacity: 95k mty), in addition to its Singapore facility in Bukom (capacity: 75k mty).

A detailed analysis of the global isopropanol market can be found in the in-demand research report “Isopropanol (IPA): 2020 World Market Outlook and Forecast up to 2029”.