Polyphenylene oxides (or polyphenylene ether) represent a group of thermoplastic polymers that are manufactured via oxidative dehydrogenation of 2,6-disubstituted phenols. Being fully miscible with polystyrene, polyphenylene oxides actually are blends of polyphenylene ether with other polymer products (and additive packages), like general-purpose or high-impact polystyrenes, polyamide, polypropylene, or styrene-ethylene-butylene-styrene copolymer. As other polymer-based products, they feature customizable and versatile functionality to be generally used in structural parts and components, like impellers, valves, meters, insulators, connectors, and boxes, in a wide range of applications, including car-making, electrical engineering, and electronics, household devices, medical instruments, office appliances, air separation membranes, energy industry, etc.

Such wide versatility mitigates the impact of the COVID-19-induced crisis on the market for engineering polymers. However, the market for polyphenylene oxides is still seriously impacted as the struggling automotive industry remains the key outlet for polyphenylene oxide consumption. The market is also negatively affected by the cancellations or delays of international trade exhibitions, fairs, and other events in the field of engineering plastics due to uncertainty surrounding the ongoing pandemic. The continuing adverse impacts of the pandemic on the polyphenylene oxide market might be offset by the quick restoration of the Chinese market, which dominates the demand for polyphenylene oxides.

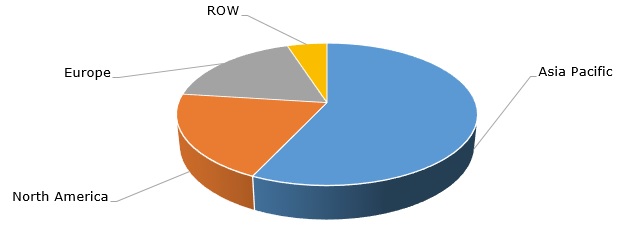

Structure of the global demand for polyphenylene oxides by region

Typical for the modern polymer industry, polyphenylene oxide application implies high-tech decisions and strong consideration of environmental concerns. For instance, polyphenylene oxides manufactured by SABIC under the brand name of Noryl can be in line with post-consumer recycling. The latter means SABIC’s commitment to developing a circular economy for plastics, as well as its proprietary TRUCIRCLE portfolio. This portfolio includes certified circular polymers which are made from the upcycling of mixed and used plastics. SABIC and Plastic Energy are currently involved in the construction of a facility for the production of certified circular polymers in Geleen, the Netherlands. The launch of the facility is scheduled for the second half of 2022. In general, the sustainability trend finds its manifestation in corporate social responsibility and corporate social innovation campaigns and activities of all polyphenylene oxide manufacturers.

As alluded to before, polyphenylene oxides are at the forefront of innovative high-tech decisions. For instance, Asahi Kasei develops an innovative housing for batteries on the basis of its brand of modified polyphenylene ether, known as Xyron. Likewise, Mitsubishi Chemicals manufactures an analogous product under the brand name of Iupiace. This application of polyphenylene oxide allows for a compact design and increased safety of batteries.

Innovative solutions in developing new resin systems lead to increased versatility and customization of products. RTP Company is one of the global leaders in custom specialty compounding, enhancing available resin systems with multiple additive packages to obtain proprietary formulations of desired products. The strengths of this company include innovation, superior technologies, unique product portfolios, excellent feedback to customer needs, and wide geographic coverage with a range of manufacturing facilities and technical centers. Such a combination permits RTP Company to constantly expand its facilities, enhance offerings and build up customer relationships. The realization of these activities, amid the current crisis-driven uncertainty, signifies that the company is convinced of good prospects of the market for custom engineered thermoplastics.

More information on the global polyphenylene oxide market can be found in the in-demand research report “Polyphenylene Oxide (PPO, PPE) 2020 Global Market Review and Forecast to 2029”.