Dimethyl terephthalate (DMT) is a functionally versatile intermediate with a wide range of applications within the production chains of other downstream products. Dimethyl terephthalate is predominantly used to make polyethylene terephthalate (PET) and other linear polyesters, which are in turn employed in different sectors, like specialty polymer products, packaging, and textiles. PET can be produced via two routes, i.e. via esterification of ethylene glycol with terephthalic acid or dimethyl terephthalate. Since the use of terephthalic acid is a more economically viable route, the use of DMT for this purpose is significantly compromised, which is a major challenge for the DMT market. Nevertheless, DMT is indispensable in the production of 1,4-cyclohexanedimethanol. Therefore, the orientation on such unique DMT applications and DMT role in the technical plastics industry offer opportunities for such companies as Oxxynova, which focuses exclusively on the production of dimethyl terephthalate.

Traditionally, DMT is derived from paraxylene and methanol, so the DMT market follows the trajectory of the upstream markets for paraxylene and methanol. With the current rise of methanol prices in the US and Europe due to limited supply and healthy demand, this upsurge in feedstock costs might drive the DMT market. The US and Europe are the regions that operate the largest DMT-producing capacities.

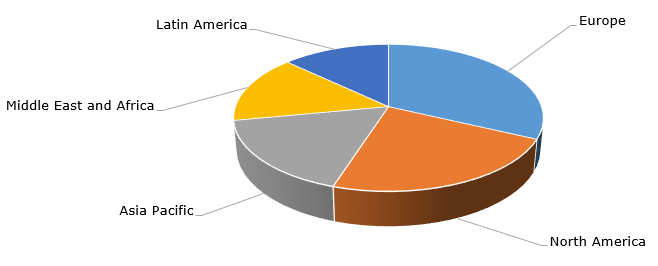

Dimethyl terephthalate: structure of the global production capacity by country

With the current focus on the circular economy strategy demonstrated by various companies, is it possible to ascertain that the long-term trend of the plastic industry lies in the active utilization of plastic waste. This in principle can lead to a decrease in the usage of raw materials and other intermediate polymeric products, like DMT. For instance, Eastman Chemical (US), which is a major manufacturer of DMT, plans to build a PET depolymerization plant in the US by late 2022. The facility will depolymerize the waste into ethylene glycol and DMT, thus potentially reducing the demand for new DMT quantities as Eastman’s polyester renewal technology enables the practically infinite number of material lifecycles. In January 2022, Eastman announced the construction of the analogous plant in France. This will be the world’s largest plastics recycling facility, which will assist in reaching the ambitious goal set by France to generate 80% less GHG emissions during material manufacturing in comparison with conventional production methods.

Find more cutting-edge information on the global dimethyl terephthalate (DMT) market in the in-demand research report “Dimethyl Terephthalate (DMT): 2021 World Market Outlook and Forecast up to 2030”.