Acetic acid is an indispensable industrial chemical involved in complex value chains and intricate commodity networks, incorporating multiple stakeholders, manufacturing entities, and technological processes. Manufactured from ethanol or methanol (including bio-based materials), acetic acid is then transformed into a range of intermediate and downstream products. Among such products, vinyl acetate monomer (VAM) accounts for over 35% of global acetic acid consumption. Other valuable intermediates include acetate esters (e.g. ethyl acetate / ETAC), with 15-20% of global acetic acid consumption, and acetic anhydride, with 15-20% of global acetic acid consumption. Additional major acetic acid outlets are as follows: polyvinyl acetate, polyvinyl alcohol, and purified terephthalic acid (converted to polyethylene terephthalate). All these chemicals are fundamental for manufacturing solvents, paints, coatings (e.g. automotive, architectural), adhesives, packaging, synthetic fibres, fabrics, food preservatives, pharmaceuticals, and agriculture intermediates, to name only a few. Global acetic acid output exceeds 17 million metric tonnes per year.

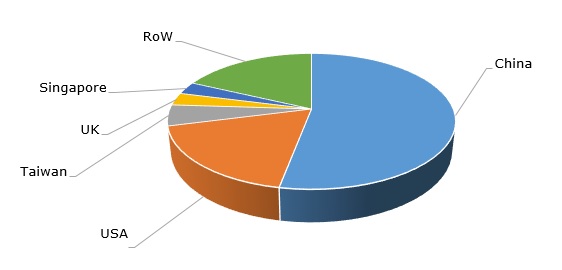

Main acetic acid producing countries, 2022

The current situation in the global acetic acid market remains uncertain and excessively volatile, which adversely affects the acetic acid market dynamics. The market-destabilizing factors include the following: recent spikes in energy and feedstock prices, high inflation, disrupted logistics, unstable political climate, and reduced demand on various end markets. For example, Eastman Chemical Co., which is among the key acetic acid producers globally, marked major customer inventory destocking across nearly all markets at the end of 2022, in contrast to traditional end-of-year destocking patterns. This may signify a more pervasive trend of the imminent global economic slowdown. Likewise, Celanese, which is another major acetic acid manufacturer, reported about accelerated destocking, poor demand in Asia, and disrupted supply chains due to inclement weather conditions.

Nevertheless, Eastman undertakes significant sustainability-focused efforts by engaging in acetic acid production in a way circular economy prescribes. The company developed an innovative molecular recycling technology that allows producing acetic acid from waste materials (e.g. plastic package) to make cellulose acetate yarn and fibre. Celanese follows the suit in sustainability activities. Celanese consistently conducts Life Cycle Assessment for acetic acid, as well as for other upstream and downstream products.

Gain in-depth insights into the global acetic acid market scenario, trends, and prospects in the in-demand research study “Acetic Acid (AcOH): 2023 World Market Outlook and Forecast up to 2032”.