Caprolactam (CPL) or epsilon-caprolactam (as a member of the class of caprolactams) is a widely used chemical intermediate consumed to manufacture nylon 6 fibres (65% of CPL use) and polyamide engineering plastics (30% of CPL use). Nylon carpets, rugs, textiles, and manufacturing yarn are quite common. Noted for their superior mechanical strength and other advanced characteristics, polyamide engineering plastics are a popular material in the automotive industry, electronics, specialty film packaging, and wire and cabling applications, to name only a few.

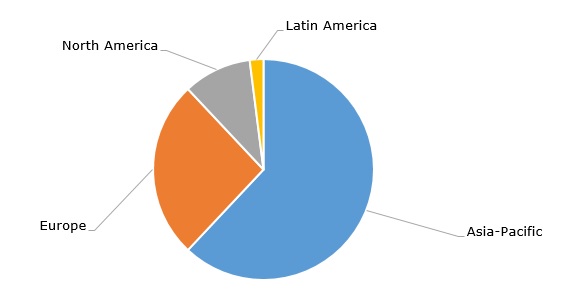

Caprolactam is mainly produced via an industrial route which involves the oxidation of cyclohexane to form cyclohexanone. Other CPL-manufacturing technologies, including those based on renewable feedstock, have been developed by such companies as BASF, DSM, Toray, DuPont, EniChem, and Sumitomo. The current global caprolactam production capacity is about 9 million metric tons per year. The caprolactam market is dominated by Asia-Pacific, which will continue to demonstrate a long-lasting trend of strengthening its leading position in this market.

Caprolactam: structure of the production capacity by region, 2022

Another major trend in the caprolactam market is associated with environmental concerns as caprolactam manufacturing can pose certain challenges in this domain. For example, Sinopec Baling Petrochemical plans to relocate its key caprolactam plant away from the existing urban area because of its potential risk to the local residents. The company operates a 300k mty caprolactam capacity at Yueyang, Hunan province, and is a major caprolactam manufacturer in China.

Environmental impacts linked with caprolactam production can be also handled via the implementation of new technologies. To illustrate this point, one can mention the EcoLactam solution developed by Fibrant. EcoLactam is a low-carbon footprint family of Fibrant’s products built around caprolactam. By realizing this holistic solution, Fibrant managed to significantly reduce caprolactam carbon footprint as compared to regular caprolactam. Fibrant is part of Highsun Group China, which is the world’s largest caprolactam producer with production facilities in the Netherlands and China. In 2018, Fibrant shut down its US-based caprolactam facility in Augusta. Likewise, in Q1 2023, BASF shut down its 170k mty caprolactam unit in Ludwigshafen (Germany). BASF will continue to operate its 300k mty caprolactam facility in Antwerp (Belgium) to cater to the European market.

Find a comprehensive analysis of the global caprolactam market in the in-demand research report “Caprolactam (CPL): 2023 World Market Outlook and Forecast up to 2032”.