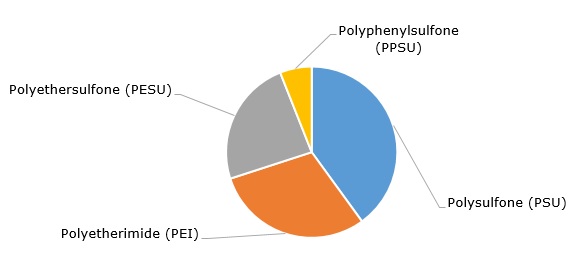

The large family of high-performance amorphous thermoplastic polymers is represented by polysulfone (PSU), polyphenylsulfone (PPSU), polyetherimide (PEI), and polyethersulfone (PESU). According to the polymer typology applied by BASF, polyarylsulfones comprise PSU, PESU, and PPSU. Polyarylsulfones are known for their high thermal, structural, and chemical stability. They are used in a broad range of advanced and innovative applications in multiple areas, including electronic, automotive, and aerospace industries, as well as medicine, water treatment, personal care, household commodities, and the agri-food sector.

Structure of the market for high-performance amorphous polymers by type

Polyarylsulfones feature several key tradenames. Ultrason is an umbrella tradename for BASF’s polyethersulfone (Ultrason E), polysulfone (Ultrason S), and polyphenylsulfone (Ultrason P). BASF’s total production capacity of Ultrason polyarylsulfones accounts for 24,000 metric tonnes per year. BASF produces Ultrason resins in Ludwigshafen (Germany) and Yeosu (Korea).

In a manner somewhat different from BASF, which associates polyarylsulfones with PSU, PESU, and PPSU, Syensqo attributes PPSU to a group of sulfone polymers. Formed in 2023, Syensqo is a world leader in high-performance specialty polymers and a spin-off from Solvay Group. Syensqo now handles the key tradenames of Solvay’s sulfone polymers, like Udel (polysulfone), Radel (polyphenylsulfone), and Veradel (polyethersulfone). Via its strategic partnership with Solvay, polyphenylsulfone products under the Radel brand are also manufactured by Westlake Plastics, alongside its Thermalux brand of sulfone materials. Likewise, a new licensing agreement permits RTP Company to produce and sell Radel PPSU resins.

Each polyarylsulfone tradename combines a wide variety of grades with different characteristics. For instance, the lineup of polyethersulfones manufactured by Sumitomo Group under the SUMIKAEXCEL tradename includes various powder, unreinforced, and glass fibre-reinforced pellet grades. Sumitomo Chemical operates two polyethersulfone production facilities of about 3,000 metric tonnes each, located in Ichihara City and Niihama, Japan.

As previously alluded to, the market for polyarylsulfones is characterised by grade versatility and multifunctionality. This assists in safeguarding the high level of product customization, customer relationship building, and resilience in case of market turbulence. This is especially true in the current macroeconomic environment, marked by decreased demand across various polymer-consuming sectors. The consumption of specialty polymers remains robust, but it is strongly susceptible to the impact of the current uncertain macroeconomic situation.

Find a comprehensive analysis of the global polyarylsulfones market in the insightful research report “Polyarylsulfones (PSU, PESU, PEI, PPSU) 2024 Global Market Review and Forecast to 2033”.