Polyphenylene sulphide (PPS) is a high-performance engineering thermoplastic which demonstrates a useful combination of properties, such as high thermal and dimensional stability, excellent chemical, corrosion and fire resistance, low toxicity, good rigidity and toughness, as well as excellent processing capacity. In its pure form and manufactured as standard PPS grades, polyphenylene sulphide is brittle, but it could be reinforced (e.g. by carbon fibre or an inorganic filler).

Polyphenylene sulphide is a versatile material, used in automotive, electronic/electrical, aerospace, telecommunications, pharmaceutical and many other industrial and consumer applications. Its ability to form composites (e.g. with carbon black, graphite, graphene, nanotubes etc) and adhere with multiple substrates increases its potential to target various markets and their segments. Polyphenylene sulphide can be produced by polymerization of para-dichlorobenzene and sodium sulphide in an organic solvent.

Polyphenylene sulphide market value exceeds USD 1.5 bn, while global demand for polyphenylene sulphide currently grows by 4-5% per year, driven mostly by such sectors as electrical and electronic equipment, automotive parts, medicine and telecommunications. However, it should be stressed that some novel applications may pose challenges for the polyphenylene sulphide market. For instance, electric vehicles may be better suited with less heat-resistant engineering polymers, such as polyoxymethylene or polypropylene, instead of high heat-resistant engineering polymers, like polyphenylene sulphide, which is more expensive and has a bigger carbon footprint.

Key polyphenylene sulphide trade names include Durafide (Polyplastics / DAICEL Group), Fortron (Celanese), Xytron (Envalior, which was recently formed by DSM Engineering Materials and Advent-LANXESS High Performance Materials), Ryton (Solvay) and TORCON / TORELINA (Toray Group). On par with Europe and Asia Pacific, the polyphenylene sulphide market in the United States is a major PPS market.

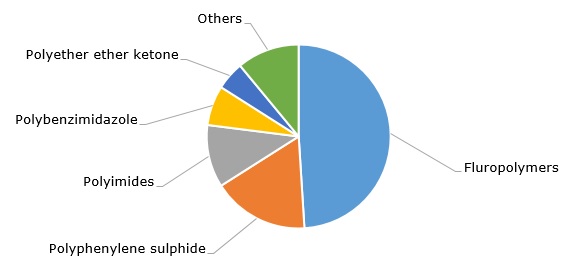

The US market for high performance polymers, by value (2023)

The market for high-performance polymers is known to be an arena for innovations, R&D activities and sustainable initiatives. Toray Industries recently announced about the development of a technology for recycling its glass fibre-reinforced polyphenylene sulphide. The technology allows obtaining recycled PPS with performance very close to virgin PPS. This technology significantly reduces carbon footprint of the company and assists Toray in reaching its sustainability targets. Solvay Group develops innovative polyphenylene sulphide polymers of Ryton brand for e-mobility, which assists in reducing charging times and increasing driving ranges. Celanese Corporation is now running a carbon capture and utilization project at its facility in Clear Lake, Texas.

The beginning of 2024 witnessed improved demand for high-performance polymers and reduction in their inventories. However, these improvements are likely insufficient to significantly correct the unstable macroeconomic situation in 2024.

Find a detailed analysis of the polyphenylene sulphide market in the in-demand research report “Polyphenylene Sulphide (PPS) 2024 Global Market Review and Forecast to 2033”.