Dimethyl terephthalate (DMT) is a high-production volume chemical intermediate, which is predominantly used to make polyethylene terephthalate (PET) and other linear polyesters (e.g. polybutylene terephthalate). For example, dimethyl terephthalate can be applied to manufacture 1,4-cyclohexanedimethanol, which is further employed to make polyester resins. Global PET production capacity currently exceeds 33 million tonnes per year. In turn, PET is used for various end markets, including packaging (e.g. for beverages, edible oil, and foods), textile synthetic fibres (referred to as polyester in the textile industry), home insulation, electronic components, microwave foils, specialty plastics, etc.

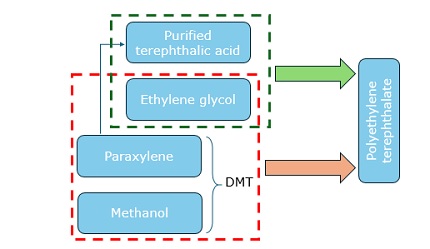

Basically, PET-manufacturing pathways can involve several options of which the following two are the most common methods: (a) esterification of ethylene glycol with purified terephthalic acid or (b) transesterification reaction between ethylene glycol and dimethyl terephthalate.

Typical PET-manufacturing routes

Sustainability initiatives are incorporated within PET-manufacturing process. For instance, Eastman Chemical depolymerizes waste polyesters with the help of heat, pressure, and methanol to generate monomers, such as dimethyl terephthalate and ethylene glycol, which can be further reintroduced into the polyester chain to make new polyesters from these recycled materials. This is called an innovative technology leveraging methanolysis. Eastman Chemical has currently secured funds from the US government for the further manifestation of a large methanolysis-based project known as a chemical recycling plant in Longview, Texas.

Since PET production can bypass the use of dimethyl terephthalate via the application of purified terephthalic acid (PTA) as a more economically viable manufacturing route as compared to DMT involvement, the steady trend to decrease DMT production has been evident for many years, especially in Europe. To illustrate the point, one can mention the operation of Oxxynova, which was until recently a leading producer of DMT in Europe. Oxxynova shut down its German plant in December 2022, which put the DMT production site on a stand-by mode effectively as of early February 2023.

The restructuring of the PET-related business is also an ongoing trend, which might also lead to the gradual phasing out of the DMT-incorporating route. For example, in 2016, Indorama Ventures Public Company Limited (IVL), a global chemical producer, acquired 100% of the PET and PTA assets of Cepsa Química S.A. Later, in 2019, Indorama acquired INVISTA Resins & Fibers GmbH, which owned a PET manufacturing facility located in Gersthofen, Germany.

Find a detailed analysis of the dimethyl terephthalate market in the in-demand research report “Dimethyl Terephthalate (DMT): 2024 World Market Outlook and Forecast up to 2033”.

A detailed analysis of the polyethylene terephthalate (PET) market is available in the in-demand research report “Polyethylene Terephthalate (PET): 2024 World Market Outlook and Forecast up to 2033”.