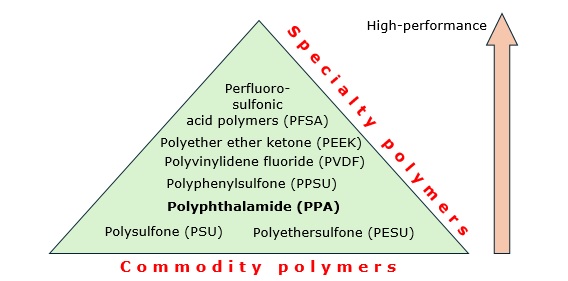

Polyphthalamide (PPA) is a high-performance engineering polymer with more advanced mechanical and thermal properties as compared to conventional commodity polymers. For instance, its melting point could peak 325°C, which is impressive for a polymer. In general, PPA is firmly embedded in the range of other specialty polymers. It is manufactured by mixing terephthalic and/or isophthalic acid with various diamine co-monomers (e.g. decamethylene diamine or hexamethylene diamine). However, in order to qualify to be called PPA, the percentage concentration of either or both of these acids should be not less than 55%. This somewhat loose requirement provides a significant degree of adaptability of PPA, making it applicable for both niche and more general applications.

Polyphthalamide positioning among specialty polymers

Polyphthalamide is widely used in the automotive industry, especially in the electric vehicle sector, which exhibits often more stringent requirements for polymer thermal stability and electrical properties due to various exploitation and safety peculiarities of EV cars. For example, Syensqo, which was carved from Solvay as a specialty chemical company in late 2023, manufactures an Amodel range of polyphthalamide products (especially the Amodel Supreme brand), which are specifically well adapted to the EV sector. Syensqo makes various products for this sector, such as polyvinylidene fluoride thermoplastic fluoropolymer applicable as a lithium-ion binder and separator coating in batteries. Likewise, Arkema manufactures its Rilsan PPA-based range of materials to serve the automotive industry components and systems. Polyphthalamide is also used in the electrical and electronic industries, aircraft, medicine, papermaking, home appliances, tubing, and other applications.

In Q1 2024, the global market for polyphthalamide demonstrated better performance as compared to late 2023, when reduced demand might be partially attributed to the factor of seasonality. However, it is too early to decide whether the improvement of Q1 2024 can be called a trend that signifies a broad macroeconomic recovery of the market. The specialty polymer sales remain rather flat, and there is a large element of uncertainty with respect to the PPA market behaviour when the situation is aggravated by demand weakness and increased logistics costs. As for long-term perspectives, the market exists at the intersection of innovation and sustainable solutions, which has been demonstrated by such an innovative and technological company as DuPont. For instance, its PPA-based Zytel HTN range of resins can effectively combine excellent polymer performance with the ability to serve various sustainable and high-tech applications, thus reducing carbon footprint and acting as a next-generation material.

Find a comprehensive analysis of the polyphthalamide (PPA) market in the in-demand research report “Polyphthalamide (PPA) 2024 Global Market Review and Forecast to 2033”.