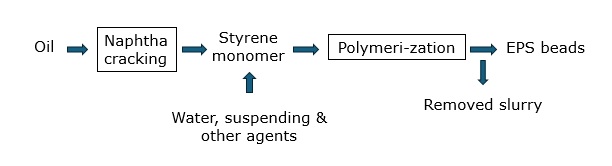

Expandable polystyrene (EPS) is a versatile polymeric foam used in a vast range of commercial applications and industries, including packaging, construction (especially, when EPS is employed as an energy-efficient, durable, light, and robust insulation material), electronics, electrical goods, the automobile industry, healthcare, disposable tableware, to name only a few. As part of the Big Six group of plastics, which also includes polystyrene, expandable polystyrene is a large-tonnage commodity with a global production capacity amounting to almost 11 million tonnes per year. Global EPS consumption is 8.3 million tonnes per year with Asia Pacific accounting for around 60-65% of the global consumption. Originating from aromatic hydrocarbons and obtained by naphtha cracking, styrene monomer is further polymerized to form EPS via the batch or impregnation process.

Expandable polystyrene production process (batch method)

It is clear from the above figures that the global EPS market is characterized by excessive production capacity, which significantly affects the market dynamics, reduces capacity utilization rates, and decreases profit margins. This trend has been evident for a long period of time, especially in the light of massive EPS capacity expansions in Asia Pacific, especially China, over the recent years. As a result, companies, such as INEOS Styrolution, may start the process of restructuring their existing production capacities by eliminating redundant ones. The process may be invigorated by reduced demand in various EPS-consuming sectors, the current unstable and challenging macroeconomic situation, pressure from environmental NGOs, and new policy regulations regarding polymer recycling. Confronted by such factors, various countries (e.g. Japan) have to reduce their EPS output.

The lack of clarity around polymer-recycling regulation, the shortage of recycled polymers, and the recycling infrastructure, exacerbated by insufficient financing of the recycling sector, drive the concerns of polymer producers. Despite these and other challenges, companies (e.g. AmSty) have been developing PS and EPS recycling systems and entities, like the Polystyrene Recycling Alliance, which is an organization entitled to expand polymer recycling. Various initiatives in this direction confirm that sustainability remains a key megatrend of the global polymer industry.

Find a comprehensive analysis of the expandable polystyrene market in the in-demand research report “Expandable Polystyrene (EPS): 2024 World Market Outlook and Forecast up to 2033”.