Epichlorohydrin (ECH) is a chemical intermediate known for its important role in the manufacture of epoxy resins. Globally, epoxy resin production accounts for over 80% of ECH consumption. Epichlorohydrin is used in the textile industry, paper and paperboard products, air/water treatment chemicals (for combatting water and air pollution), cosmetics, automotive and aircraft parts, pharmaceuticals, agriculture and foods, construction, as well as in a range of other industries. It can be polymerized to form various elastomers and rubber products, applicable as seals (e.g. automotive seals), gaskets, rubber rolls (e.g. for copier machines), cable sheaths, adhesives, hoses, belts, to name only a few. ECH-based products are known for excellent performance when consumers require augmented heat and oil resistance, as well as advanced low-temperature and semiconducting properties.

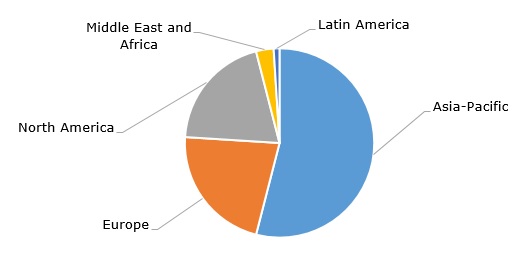

Global epichlorohydrin production grew from 1.68 mln tonnes in 2015 to 2.3 mln tonnes in 2023 with a potential to reach almost 3 mln tonnes by 2030. Asia Pacific accounts for the largest share of global epichlorohydrin production.

Epichlorohydrin (ECH): structure of the global production by region, 2023

ECH production overcapacity in Asia-Pacific has recently become more vivid against the background of reduced demand in various ECH-consuming sectors. Despite this trend, additions to Asia-Pacific’s epichlorohydrin production capacity are forthcoming. For instance, DCM Shriram, a diversified agrichemical and chloro-vinyl firm, plans to launch a new epichlorohydrin plant in Jhagadia, Gujarat (India) in fiscal 2024-2025.

Epichlorohydrin is typically produced by reacting hypochlorous acid with allyl chloride, which is in turn manufactured by using propylene and chlorine. The technology of using renewable bio-based glycerol to make epichlorohydrin has been already widely employed to replace petroleum-based epichlorohydrin. The amount of 35 tonnes of glycerol, which is a popular waste product of bio-fuel production, can yield 27 tonnes of epichlorohydrin (biodiesel and epichlorohydrin production are often coupled). Solvay is currently actively involved in licensing its proprietary glycerol-to-ECH Epicerol technology after it sold its bio-ECH business (a 58.77% stake in a Thai subsidiary, Vinythai PCL) to the AGC Group, formerly Asahi Glass Co. AGC Vinythai Public Company Limited (Thailand), established in 2022, now handles this bio-ECH business. The use of renewable feedstock to produce various commodities is a powerful trend, which has been gaining momentum.

Find a comprehensive analysis of the epichlorohydrin (ECH) market in the insightful research report “Epichlorohydrin (ECH): 2024 World Market Outlook and Forecast up to 2033”.