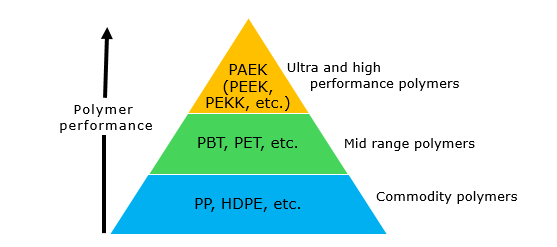

PEKK (polyether ketone ketone) and PEEK (polyether ether ketone) are both ultra-performance thermoplastic polymers that belong to the polyaryl ether ketone (PAEK) family of thermoplastic polymers. The PAEK family includes over 300 known polymer variants, but only a select few have been commercialized since their introduction to the market in the early 1980s (their development occurred even earlier). These materials earned their reputation for exceptional performance under high stress, elevated temperatures, and exposure to aggressive chemicals. PAEK polymers are at the very top of the polymer performance pyramid.

Polyether ketone ketone (PEKK) and its place among other polymers

Polyether ketone ketone (PEKK) contains a higher proportion of ketone groups in its molecular structure, specifically, an additional ketone group, compared to polyether ether ketone (PEEK). This structural difference results in distinct performance characteristics. Beyond PEEK and PEKK, the arrangement of ether (E) and ketone (K) units within the polymer backbone can vary, giving rise to different types of PAEK (polyaryl ether ketone) polymers, such as PEEKK or PEKKK. Both PEEK and PEKK can be blended or compounded with other polymers to form composites. PEKK, in particular, can exhibit both amorphous and crystalline phases. PEKK offers superior compressive strength, increased rigidity, and excellent chemical resistance to acids, solvents, and oils. These properties make PEKK especially suitable for demanding applications in industries such as aerospace, automotive, and oil and gas. Additionally, both PEKK and PEEK are widely used as biomaterials in the dental and medical fields. For example, the annual consumption of medical-grade PEEK in North America exceeds 670 tonnes.

It is clear that future research will inevitably uncover new areas of application for PEKK, particularly driven by global sustainability megatrends. According to Arkema, the growing demand for lightweight materials capable of withstanding the most extreme conditions has been a key factor in the increased interest in this polymer. Such harsh environments are commonly found in sectors like aerospace (where PEKK was originally developed under the Apollo space programme) and offshore oil extraction.

Arkema manufactures PEKK under the Kepstan tradename and operates Europe’s first industrial-scale production facility for PEKK, located in France. Interestingly, despite the macroeconomic uncertainty of the past year (which only intensified in Q1 2025), 2024 was a successful year for Arkema’s Specialty Materials Division. The division recorded stable growth of 3.4% compared to 2023, driven primarily by strong performance in the high-performance polymers sector. This segment experienced solid growth in markets such as batteries, sports, energy, and medical applications. However, it was negatively affected by a slowdown in the automotive market during the second half of 2024, particularly in Europe. This trend is likely to continue, especially in light of the ongoing trade war. Nonetheless, PEKK and PEEK production may be considered a relatively safe haven amid market fluctuations. In contrast, the specialty polymers division of Syensqo (a spin-off from Solvay focused on advanced materials) underperformed in 2024 compared to the previous year.

Find a detailed analysis of the PEKK market in the in-demand research report “Polyetherketoneketone (PEKK) 2025 Global Market Review and Forecast to 2034”.