Phenol, produced mainly via the cumene peroxidation process, plays an important role in the chemical and other industries. It is an indispensable building block used in the production of plastics (further processed into automotive parts, mobile phones, etc.), paints, coatings, adhesives, solvents, synthetic fibres, insulating materials, medicines, construction materials, to name only a few.

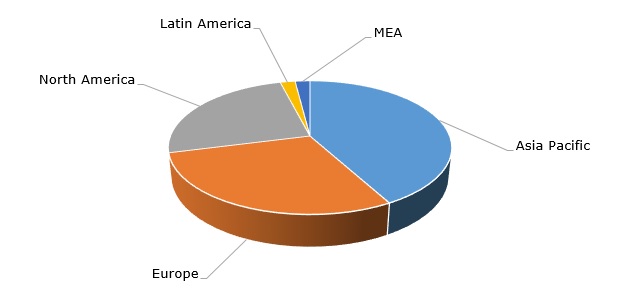

Phenol: structure of the global production capacity broken down by region

As such, the phenol industry represents a complex focal system, interacting with other systems. These involve primarily the petroleum industry, which supplies necessary feedstock for phenol production. In majority of phenol-producing facilities, cumene acts as essential raw material, being based on benzene and purified propylene. The phenol production system is partnered with other adjacent systems, for instance, the production of accompanying chemical intermediates (e.g. acetone). Finally, the phenol market is imbedded in the aforementioned end-markets.

All these systems operate in specific regulatory, business, political, social, technological and other environments. The ensuing systemic interactions form feedback loops and complex networks of causal factors, whose non-linear relationships are characterised by dynamic complexity and multiple response delays. With such level of complexity, a vertical integration of phenol business, backed by substantial technological expertise and robust marketing models, may be the most effective solution in the fast-changing market environment. For instance, INEOS Phenol (a part of Anglo-Swiss INEOS Group and the world’s largest producer o, phenol, acetone and cumene with over 2 mln mt/y in phenol capacity alone) is acting in the similar vein. The current petroleum price hike is mitigated by the company’s substantial cumene production base (Ineos plans a new cumene plant in Marl, Germany by 2020). Diversified and flexible portfolio of businesses helps Ineos Phenol to cater for different consumer markets, while the use of proprietary production technologies, as well as Badger Licensing cumene technology, provides technological prowess. Ineos Phenol keeps reasonable geographical spread of production facilities, covering all major markets, including the US, Europe and China (via JV with Sinopec Yangzi Petrochemical Company).

The company also features a relatively modest staff capacity, which helps to maintain operational cost-effectiveness. By incorporating all these approaches, Ineos Phenol holds the leading position on the market.

Find more information on the phenol market in the in-demand research study “Phenol: 2018 World Market Outlook and Forecast up to 2027”.